Introduction:

The entrapment pumps using the state of- the art single-unit auto-cascade refrigeration system. Selecting compressors and refrigeration parts of globally famous brands.ang adopting new environment-friendly mixed refrigerants. Through technological improvement the performances of Water vapor cryopump produced by our company is bettered and stabilized. These pumps feature high refrigeration speed. Low refrigerating temperature.no greasy blockage. Wider range of cooling water temperature and simple installation and operation. All indictors of which have reached the international advanced level. Therefore are very popular among users in vacuum coating.

Advantages of Water vapor cryopump

1. It can reduce the pump evacuation time by 30%-80%

2. It can improve the production capacity by 30%-100%

3. It can realize fast refrigeration and temperature recovery and can be cycle used for a long time

4. Dual-way load can be designed. And it can be installed simultaneously in the vacuum and at the oil diffusion pump inlet.

5. Liquid nitrogen which is expensive is not needed.so the cost can be recovered soon.

6. It has the perfect control system composed of a touch screen and Siemens PLC.

7. Multi-channel temperature display is realized. And the defrosting temperature can be set freely.

8. It can be installed flexibly in the existing vacuum coating system; the installation is simple and convenient. Not affected by connector, intake pipe. Valve and baffle.

9. With simple operating interface and perfect protective measures.it can realize remote control and be fully compatible with the existing vacuum coating system.

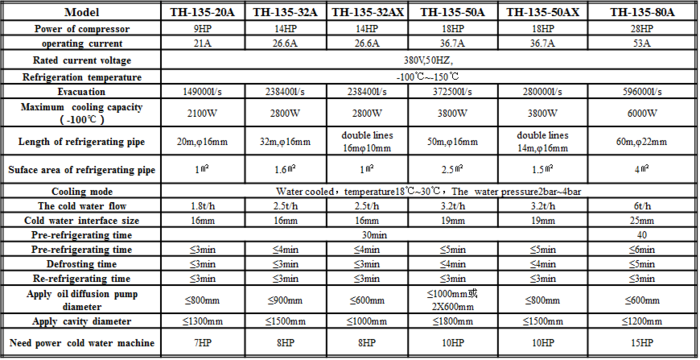

Technical Parameters

In production, the refrigerating coil of a Water vapor cryopump can be installed on the vacuum coating machine in the following three ways:

1.lt is installed in the passageway of the vacuum chamber or at she top or bottom of the vacuum coating chamber, with the main purpose to entrap residual water vapor in the air inside the vacuum chamber, increase the evacuation rate, elevate the vacuum degree, and improve the coating quality, the refrigerating coil will have frosting or condensation because of the air in flow when the door is open, required every tine before opening the door(see Fig.1 below)

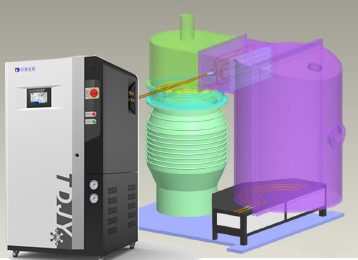

Fig.1: install in the passageway of the vacuum chamber

2. lt can be installed below the high valve at the oil diffusion pump inlet, with the main purpose to prevent the oil vapor of the oil diffusion pump from returning to the vacuum chamber and at the same time elevating the vacuum degree, Since this position is kept in the vacuum state, it is ummecessary to conduct the operation of temperature recovery on the refrigerating coil.

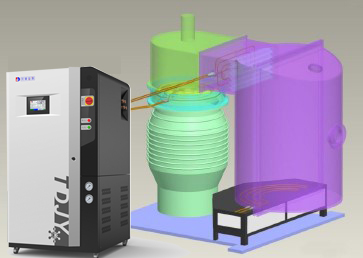

3. The Water vapor cryopump can be designed with dual-way output, so the refrigerating coil can de simultaneously installs in the vacuum chamber and at the oil diffusion pump inlet(see Fig.2 below).

Fig.2: Simultaneously install in the vacuum chamber and at the oil diffusion pump inlet.

The oretical value

When the vacuum chamber is under pressure of(1×10-4) Torr,it takes about 16min to evacuate 7,600000L of water vapor with an oil diffusion pump or molecular pump all the evacuation rate of 8000L/sec;the PC- 15P cryogenic pump is used the evacuation time at the rate of 268200L/ sec is about 1.20min and the refrigerating time is3~5min,so the totaltime=1.20min+3~5min=4.2~6.2min.